At Ray Sono, we see an exciting opportunity to rethink the everyday lives of factory workers. We aim to turn a technological leap into a human-centric revolution, focusing on the most important and scarce resource in the factory: human resources.

From blue collar to new collar: new work in the factory

The evolution of work in the factory

The integration of advanced digital tools and automated systems is transforming the traditional blue-collar landscape. This shift is not merely incremental but transformative, enabling unprecedented levels of productivity and cost efficiency. Companies must leverage these technologies to remain competitive.

According to PwC’s 27th Annual Global CEO Survey, 45% of global CEOs are not confident that their companies would survive more than a decade on their current path. This underscores the urgency for a forward-thinking strategy. As automation advances, the delineation between human and machine roles becomes increasingly blurred. A strategic approach that integrates new possibilities with actionable implementation steps is crucial.

Practical and cutting-edge solutions – beyond the hype

Sometimes the most revolutionary solutions are simple and user-centric rather than purely technological. The concept of New Work emphasises practicality and user-centricity. Rather than pursuing technology for its own sake, companies should focus on practical innovations that address real-world challenges.

For example, in one of our projects for Voith, we were tasked with creating a vision for the future operation of paper machines. Instead of introducing entirely new elements for human-machine interaction, we opted for tools familiar to the industry. We found that established elements like pressure knobs and rotary knobs, which provide haptic feedback and a tangible connection to the values they adjust, were highly valued by users.

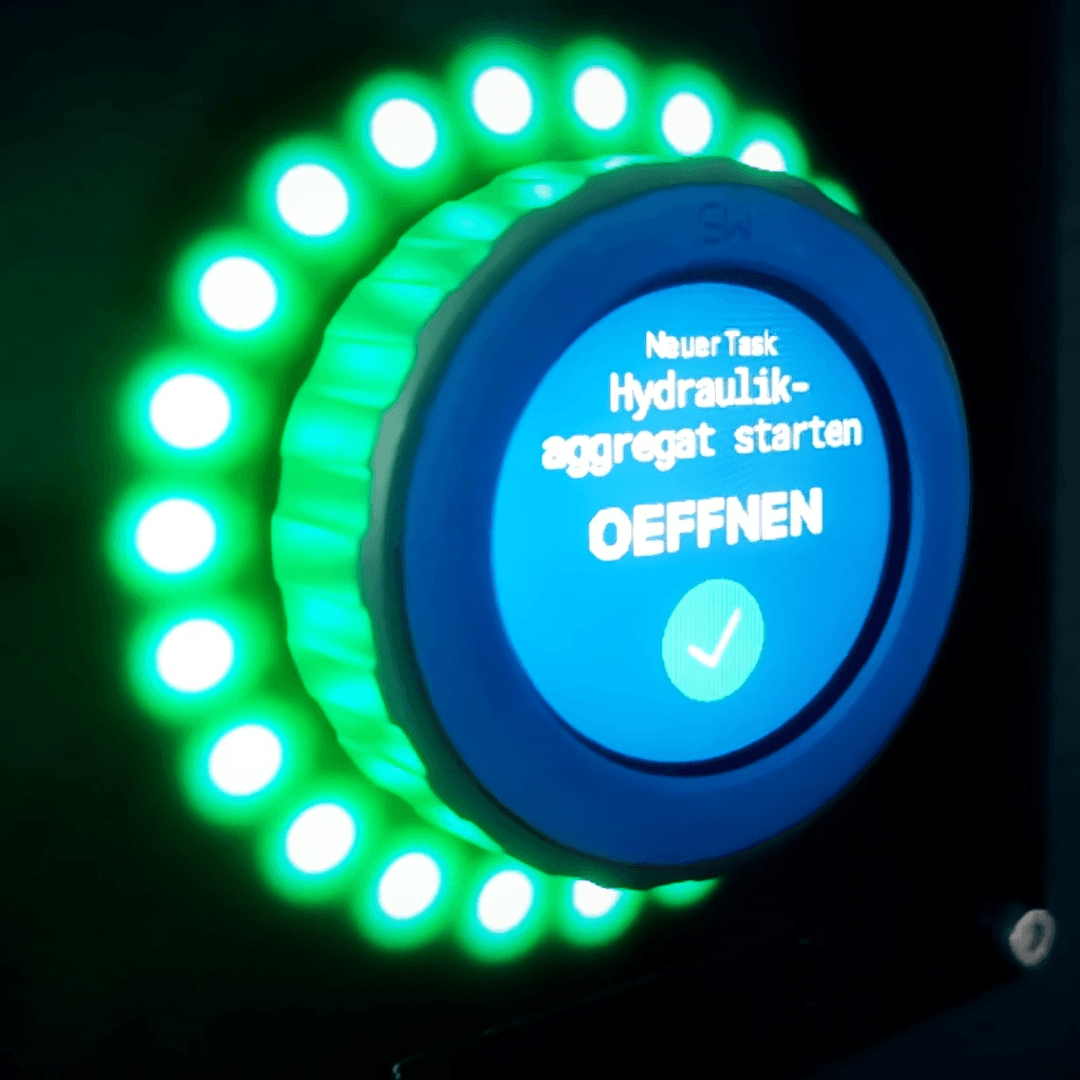

However, there were pain points with the current elements, such as the need for operators to walk across large machines to access controls. To address this, we developed the Smart Button, combining the best of both worlds: it retains the beloved interactions while eliminating pain points and meeting high safety and industrial standards.

Voith HMI: The Smart Button

For Voith, we developed a vision for future paper machine operations using a familiar control element: the Smart Button. This innovation demonstrated three key advancements:

Multiple functions assigned to a single button:

significantly reduces the number of control elements and screens paper machine operators currently have to monitor.Portability, allowing remote operation:

enables operators to manage the machine from various locations, increasing flexibility and efficiency.Seamless integration with existing IT and OT systems:

facilitates both operation and data consumption using a single device, streamlining processes and improving data-driven decision-making.

These innovations were only possible with a proven technical concept, showing that real-world feasibility is essential for gaining stakeholder confidence and driving successful implementation.

Beyond visual prototyping

Design thinking is pivotal for understanding and addressing the needs of the target user, ensuring that our solutions resonate with those who matter most. However, in co-creation projects, it's imperative to bring engineering into the conversation early. While user-centric ideation and visualisation are key drivers of innovation, technical feasibility is non-negotiable. If we overlook this, we risk losing the crucial buy-in from the tech teams. To ensure successful implementation, we must not only innovate but also validate that these ideas can be integrated seamlessly, particularly when it comes to incorporating new human-machine interactions (HMIs) into existing systems.

The Smart Button we developed with Voith is a great example:

It can be assigned several actions, showing that a single control element can fulfil multiple functions.

It is portable, allowing operators to control machines from anywhere in the facility, thus increasing efficiency.

It works seamlessly with existing IT and OT systems, bridging the gap that previously existed.

The difference between IT and OT

Information Technology (IT) manages electronic data and supports business operations, while Operational Technology (OT) controls physical devices and processes in industrial settings.

Key differences:

Focus:

IT manages data; OT controls physical processes.Environment:

IT operates in offices and data centres; OT in factories and plants.Security:

IT prioritises data security; OT emphasises operational continuity and safety.

The challenge of IT & OT separation:

While traditionally separated, IT and OT increasingly overlap in modern factories. Data generated by OT systems (e.g., sensor data) is crucial for adjusting operations, creating a continuous loop between IT and OT. Effective production relies on the seamless integration of both, balancing operational efficiency with security concerns.

Leading change: human-centric innovation

The biggest barrier to innovation success isn't technology – it's neglecting the human element. To break free from this stagnation, organisations must prioritise human-centric strategies, creating environments where innovation thrives through active engagement and buy-in at all levels.

Our study of over 100 change projects at Voith, Deutsche Bahn, BMW, and DACHSER shows that purely technical projects stagnate at a 30% success rate. Transforming innovation success involves focusing on human-centric strategies that foster active engagement and create thriving environments for change.

Minimum viable change through prototyping

Treating organisational change like product development through prototyping reduces risk and enhances adaptability. Implementing small, pivotable changes ensures a user-centred, holistic approach, in contrast to the risks of rigid, comprehensive plans. By focusing on Minimum Viable Change, organisations can be agile and strategic, making significant improvements without overwhelming the system, ensuring progress without capsizing the ship.

Bottom-up approach: understanding workforce needs

Instead of top-down directives, we prioritise understanding the real needs of our workforce through thorough research. For instance, for our client, the craft company B&O Service, we conducted extensive field research with their technicians. By immersing ourselves in their daily routines and understanding their communication needs, we designed communications formats and workflows that truly support their work.

Empower change champions for broader acceptance

True transformation is driven by empowered individuals at all levels, not just top management. Identifying and empowering early adopters as change agents ensures the message resonates across the organisation, facilitating acceptance and implementation.

Culture by design: transition from project-based to integral change

Change must evolve from isolated projects to a core component of the organisational structure. Establishing dedicated units for sustainable business development, embedding change into strategy, and ensuring continuous feedback and monitoring are critical steps.

Institutionalising change ensures it is maintained and integrated into regular management processes, making it a permanent and evolving element of the organisation. To sustain change over the long term, new behaviours and processes must be aligned with existing roles and responsibilities. By embedding these new behaviours into their culture and aligning them with employees’ personal objectives, organisations can ensure that the change sticks. Otherwise, even well-intentioned projects may end up withering away. Aligning systems, processes, and policies with the new direction further solidifies this integration.

We are calling for a revolution in human-machine collaboration

The convergence of IT and OT in the factory setting offers a unique opportunity to rethink and revolutionise the role of human workers. By focusing on practical, user-centric solutions and validating technical feasibility, we can ensure that technological advancements lead to meaningful and sustainable improvements in the workplace. At Ray Sono, we are committed to making this human-centric revolution a reality, transforming factories into environments where innovation thrives and human potential is fully realised.

Glimpse into our insights

Connect